Business case and feasibility study

Make the right investment, the first time.

Logio validates premises, defines processes, models alternatives, and quantifies returns, risks, and readiness.

Use this to compare technologies, set scope and phasing, and prepare a defendable decision for the board.

Your challenges

What’s holding you back right now?

Conflicting vendor quotes and claims

Unclear total cost vs. service trade‑offs

Hidden constraints outside the DC walls

Lack of risk scenarios and fallback plans

When it matters

You’ll benefit when you are…

Choosing between shuttle, AS/RS, AMR

Weighing greenfield vs. retrofit

Seeking financing approval

Coordinating with IT, fire safety, construction

Exploring automation for the first time

Outcomes

What we deliver

Clear premise pack

Current state, data, and constraints agreed.

Comparable variants

Tech, layout, controls, and staffing.

Board‑ready business case

ROI, risks, timeline, and KPIs.

Tender‑ready specs

Functional specs and vendor shortlist.

What makes us different

Logio experts at your service

Objective, supplier‑independent approach

Cross‑functional view including IT, safety, maintenance

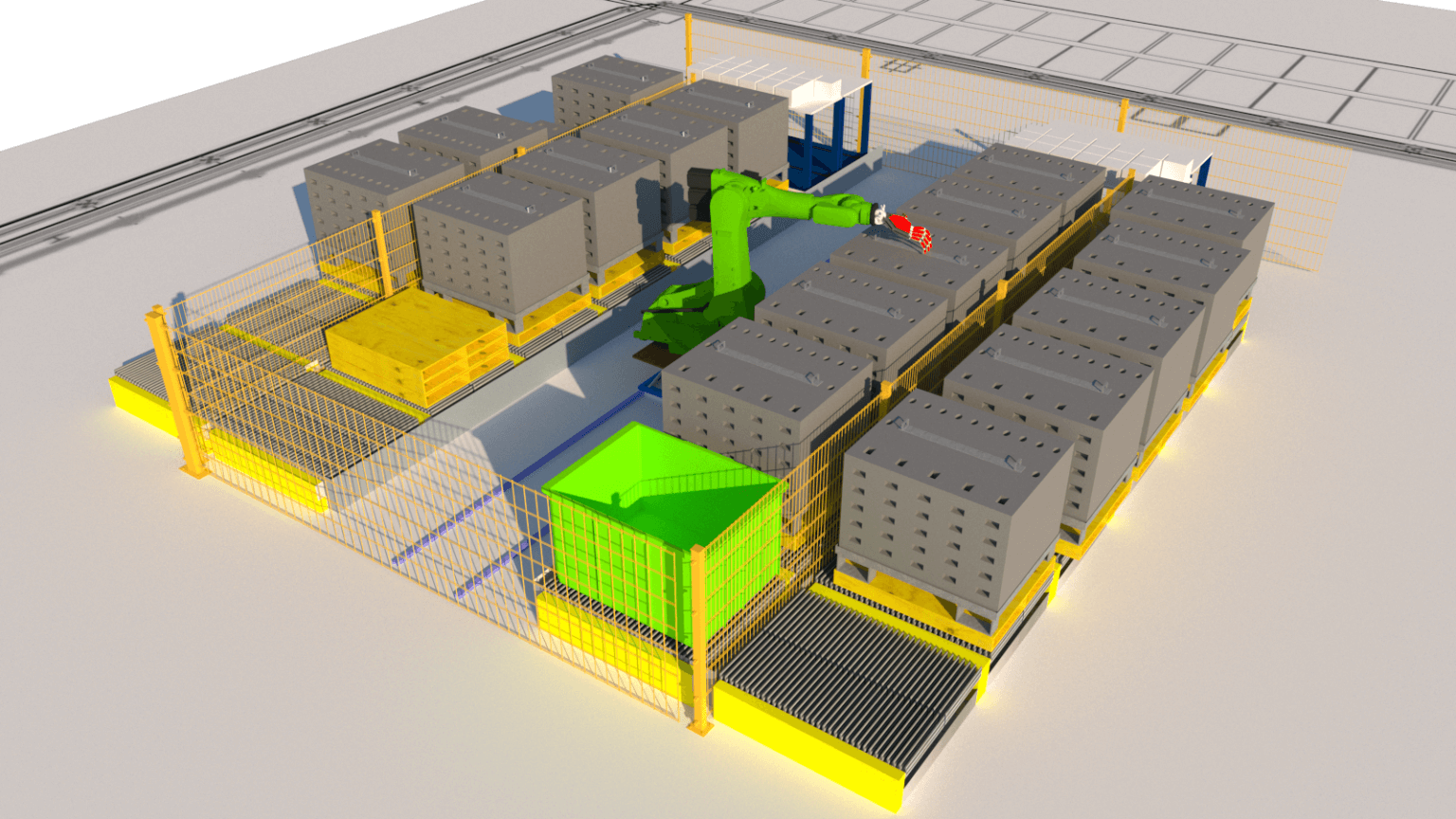

Simulation for risk/benefit verification

Experience across retail, FMCG, manufacturing

Data and AI‑first company

Feasibility is quantified with real data and dynamic modelling, not averages. Scenario analysis exposes sensitivities, from demand swings to outage modes.

Case studies

We tackled many supply chain challenges

Choose the right investment

If your board needs a defendable case with risks and returns, Logio will build it with you.