Automotive & Industrial

Lower MRO inventory with assured availability

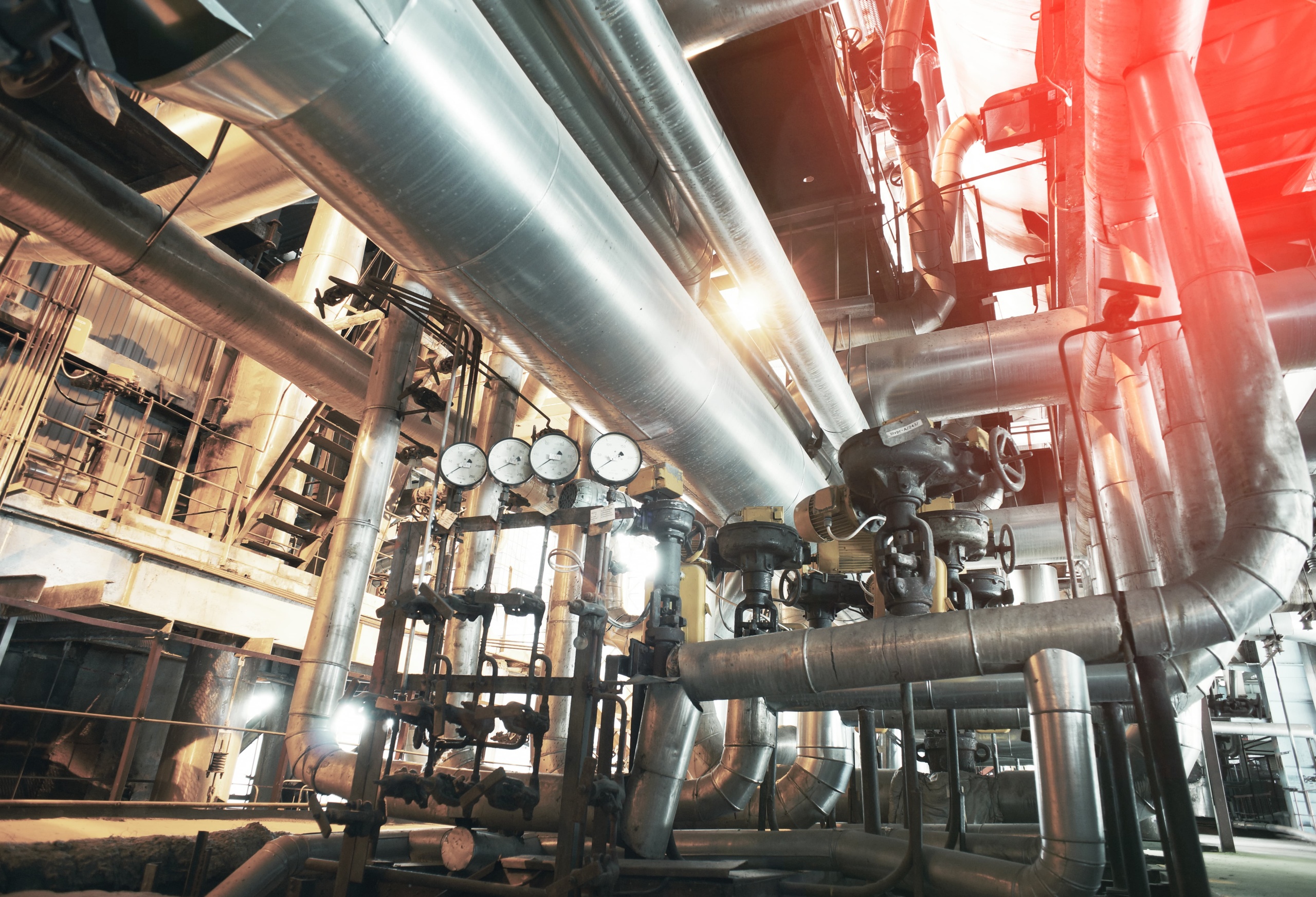

Logio partnered with ORLEN Unipetrol to right‑size spare parts and materials inventory while maintaining uptime‑critical availability.

Outcome

We segmented the portfolio, forecasted planned and unplanned consumption, and set optimal stock policies with automated purchasing. Inventory value dropped while availability risks for critical parts were eliminated.

Inventory value

-0%

Risk of critical‑part stockouts

Eliminated

About ORLEN Unipetrol

ORLEN Unipetrol is the Czech Republic’s largest refining and petrochemical group, operating two refineries at Litvínov and Kralupy and leading the country’s fuel retail market. It is part of the ORLEN Group.

5.4 mtpa capacity at Litvínov refinery

3.3 mtpa capacity at Kralupy refinery

~6,000+ employees in the Group

439 service stations in Czechia

Initial challenge

High capital tied in MRO materials and spare parts with a need to keep maintenance availability optimal.

Project goal

Reduce working capital without compromising the availability of critical spare parts.

Solution

From criticality to policy: a disciplined MRO playbook

We combined feasibility sizing, demand behavior analysis, and criticality‑based policies to optimize stock levels and streamline purchasing.

Solutions implemented

Demand Forecasting & Inventory Optimization

Business Case & Feasibility Study

Spare Parts Management

Impact

Full shelves, faster work

Inventory value reduced by 25%

Significant working‑capital release

Assured availability of critical parts

Policies based on criticality eliminated stockout risk

Automated purchasing

Faster, policy‑driven ordering for MRO items

Standardized governance

Clear segmentation and policy templates across the portfolio

Make your maintenance stock lighter and safer

If spare parts tie up capital or threaten uptime, we can help design criticality‑based policies and automate replenishment. Let’s discuss an MRO inventory program that protects availability and frees cash.

We tackled many supply chain challenges

Robotized battery sequencing for an automotive assembly line

Robotized battery sequencing cell with vision verification reduced manual handling risk and is ready for AGV integration. Business case projected a 3.5 year payback.

Warehouse design for Angry Beards

A scalable logistics concept and warehouse design that supports rapid e‑commerce growth while preparing the operation for future automation.

10‑year warehouse growth roadmap

1B CZK capacity potential designed