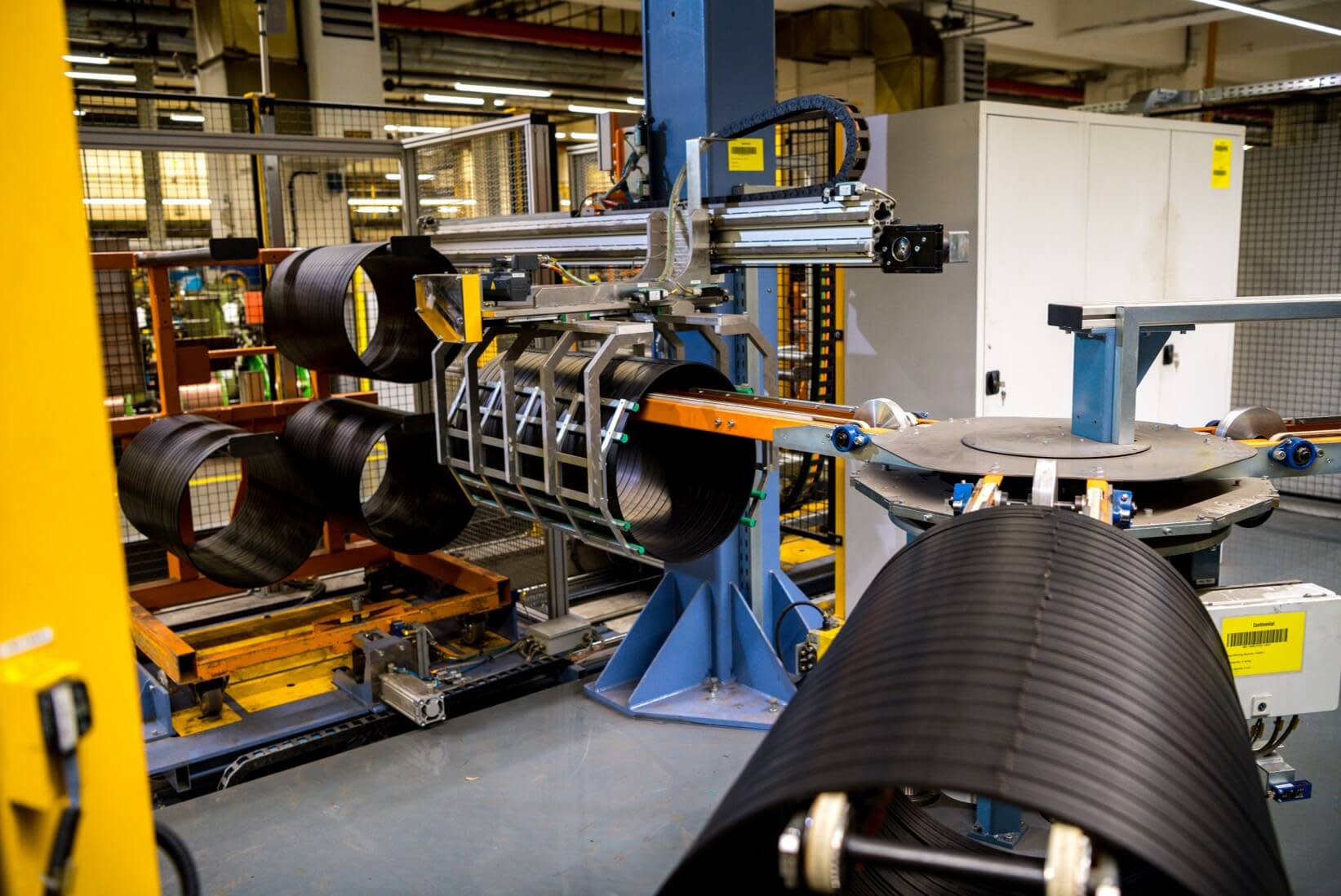

Process mapping & analysis

Map what’s happening. Understand why. Improve what matters.

We help you make sense of your current processes through structured analysis, stakeholder interviews, and data.

The result is a clear view of what’s working, what’s broken, and where to start improving. Use this when you are preparing for change, planning new systems, or need facts instead of assumptions.

Your challenges

What’s holding you back right now?

Inefficiencies are hidden in day‑to‑day work

Processes are slow, duplicated, or unclear

Reality differs from what process docs claim

Data is scattered and reporting is slow

Teams work around systems, not with them

Something's broken but we're not sure what exactly

When it matters

You’ll benefit when you are…

Planning a new ERP, CRM, WMS, or APS

Preparing for automation or RPA

Identifying cost leaks in production or logistics

Merging teams post‑acquisition

Establishing compliance or audit readiness

Standardizing ways of working across sites

Outcomes

What we deliver

Clarity & transparency

See how your processes really work, with clear visuals and metrics.

Cost control

Identify hidden inefficiencies, bottlenecks, and unnecessary costs.

Risk reduction

Uncover compliance gaps, delays, and handover risks before they escalate.

Faster transformation

Create a solid baseline for ERP, WMS, or automation.

Actionable insights

Get specific recommendations you can implement right away, not just theory.

Improved alignment

Align stakeholders around a shared understanding of processes and priorities.

What makes us different

Logio experts at your service

Hybrid team: consultants + system architects

Deep understanding of both business and tech

Ready‑to‑act outcomes, not just pretty diagrams

High adaptability to your industry and culture

Vendor‑independent view with deep industry context

AI‑first

Logio grounds diagnostics in data. Process mapping combines interviews, system exports, and on‑site observation with advanced analytics to separate signal from noise. We focus on facts, not opinions, so decisions are defensible and repeatable.

Case studies

We tackled many supply chain challenges

See your processes end‑to‑end

If operations are complex and fragmented, Logio helps you map reality and act on it with data‑led improvements. Let’s talk about what to fix first.