Automotive & Industrial Components

Faster ramp‑up with fewer bottlenecks

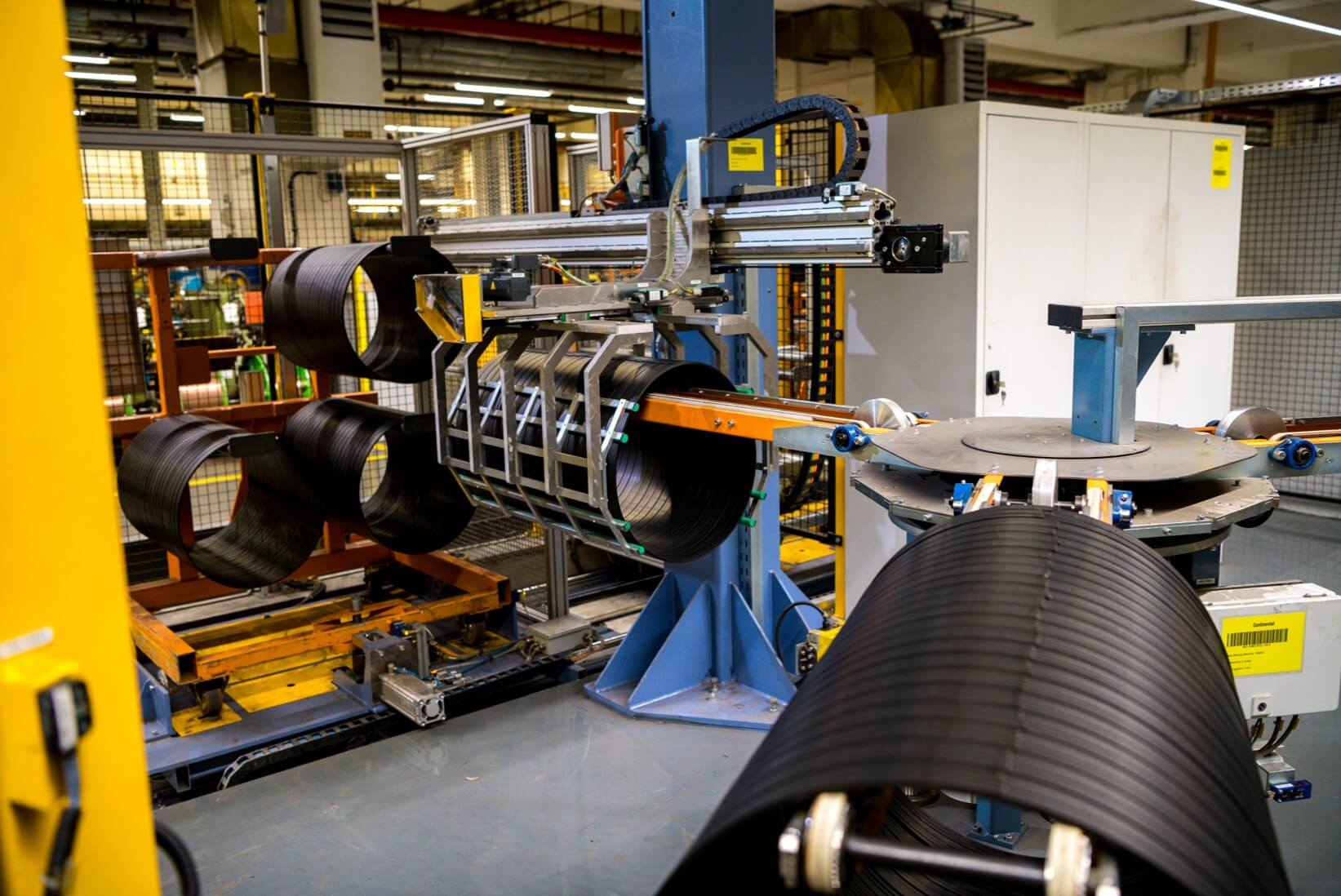

Logio supported Continental at the Trutnov plant and Barum Continental to secure a smooth production start and effective operational control using dynamic simulation.

Outcome

We tested layout and staffing scenarios in minutes, identified bottlenecks including equipment failure risks, and configured an optimal setup that met the production plan and reduced costs.

About Continental

Continental AG is a German automotive supplier founded in 1871 and headquartered in Hanover. The group operates globally across Automotive, Tires, and ContiTech and runs manufacturing in the Czech Republic, including Trutnov and Barum Continental in Otrokovice. In 2024 Continental generated €39.7 billion in sales, employed around 95,000 people, and operated in 54 countries and markets.

Sales €39.7 bn (2024)

~95,000 employees

Operations in 54 countries and markets

Initial challenge

Secure a smooth production start and set up efficient operational control at two Continental entities, Trutnov and Barum Continental.

Project goal

Validate the production line layout and workforce distribution quickly, remove bottlenecks, and establish a sustainable, continuously improving production system.

Solution

Simulate, validate, ramp up

We built a dynamic simulation of the production system, evaluated layout and staffing variants in minutes instead of weeks, and implemented the optimal configuration with a focus on stable day‑to‑day control.

Solutions implemented

Production Ramp‑up Support

Dynamic Simulation

Process Mapping & Analysis

Simulation & Flow Analysis

Impact

On‑time ramp‑up, leaner production.

Production plan achieved

Met the planned output after configuring the optimal layout and staffing.

Stable daily operations

Operational control routines created a sustainable, improving production system.

Plan your next ramp‑up with confidence

If you are preparing a new line or scaling capacity, we can de‑risk decisions with dynamic simulation and hands‑on ramp‑up support. Let’s talk about a focused approach that delivers plan adherence and lower costs.

We tackled many supply chain challenges

Intralogistics optimization for Trane Technologies

Logio mapped intralogistics, built missing data inputs, and designed a warehouse and material‑flow reorganization at Trane Technologies—targeting up to 30% productivity improvement and lower logistics costs.

Up to 30% productivity (planned)

Ergonomics‑led productivity for a steel processor

Lean housekeeping and ergonomic improvements lifted productivity fast and set conditions for healthier, more stable operations.

+10 % labor productivity in 2 months

Up to –30 % long‑term sickness expected