Dynamic simulation

Make change decisions with confidence.

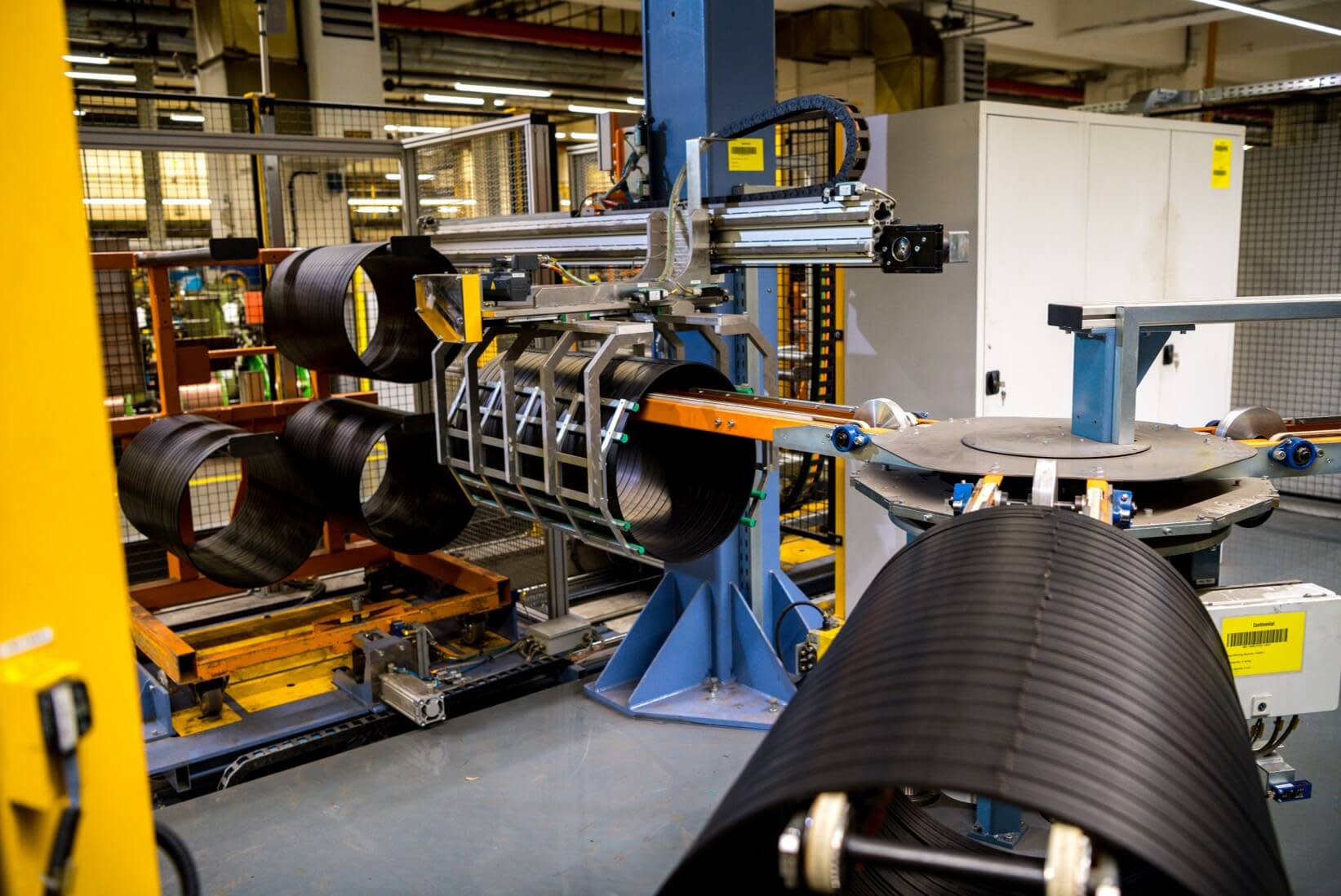

Logio builds a 3D, dynamic “digital twin” of your operation to test scenarios before you commit budget or disrupt production.

We identify bottlenecks, verify capacities, size resources, and compare design options for factories, warehouses, and internal logistics—so you choose the optimal path with lower risk and higher ROI.

Your challenges

What’s holding you back right now?

Investments are based on vendor promises, not hard data

Unknown bottlenecks and true throughput limits

Automation ROI is unclear and risky to estimate

Process changes break upstream or downstream flows

Critical scenarios aren’t stress‑tested before go‑live

When it matters

You’ll benefit when you are…

Designing a new line or warehouse

Preparing an automation feasibility study

lanning peak season or product expansions

Consolidating sites or relocating capacity

Re‑balancing labor, shifts, and equipment

Validating WMS/controls changes at scale

Stress‑testing critical “what‑ifs” and failure modes

Designing internal material flows and layouts

Outcomes

What we deliver

Bottleneck visibility

Find and remove true constraints across production and intralogistics.

Right‑sized design

Compare variants, choose the optimal layout, tech level, and staffing.

De‑risked investments

Validate capacity, SLAs, and safety stocks before you spend CAPEX.

Faster implementation

Use a verified model to align vendors, IT, and construction.

Scenario confidence

Test peak seasons, disruptions, and growth paths in a digital twin.

Clear business case

Quantified impacts and a route‑map you can execute.

What makes us different

Logio experts at your service

Vendor‑independent, objective design and evaluation.

Hybrid team: consultants, system architects, data scientists.

Feasibility to go‑live: we design, verify, and manage delivery.

Data‑driven approach combining math, simulation, and operations know‑how.

Proven in manufacturing, warehousing, and distribution across 1,000+ projects.

Data and AI‑first company

Logio uses AI where it adds real value, combining it with mathematics, data, and real‑world expertise. That means faster, more accurate decisions and fewer blind spots when you are sizing capacities, sequencing flows, or testing variant designs. AI is a tool, not a buzzword.

Our proprietary software platform, Veritico, is built on 20 years of development, trusted by 80+ customers, and listed in Microsoft Azure Marketplace. It uses machine learning for demand forecasting, price and promo decisions, and intelligent ordering—capabilities that provide high‑quality inputs to your simulation experiments and transformation roadmap.

How Veritico supports this solution

Veritico delivers accurate forecasts, inventory targets, and replenishment plans that feed simulation scenarios with realistic demand and policy settings, so your digital twin reflects how the business will actually run. This shortens iterations and improves decision quality.

Case studies

We tackled many supply chain challenges

Prove the best path before you build

Model your factory or warehouse, compare variants, and launch with confidence.