to select the optimal scenario, plan batch sizes, verify machine utilization, and size WIP and packaging.

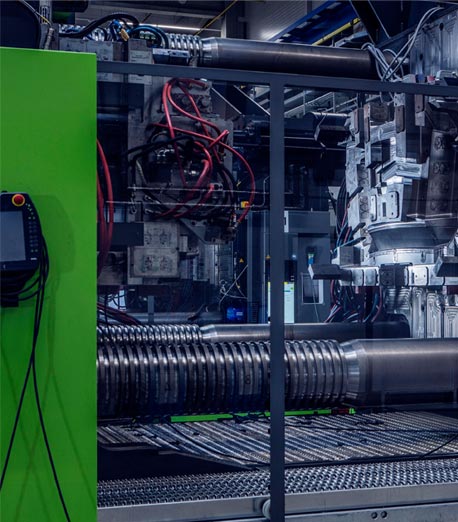

Automotive & Industrial Components

Confident start of production under tight space and capacity

Logio prepared and implemented an end‑to‑end internal logistics concept for a Megatech plant in Pilsen, integrating a new production project into existing operations.

Outcome

The solution covered material flow from receiving to dispatch and was validated with dynamic simulation, enabling a smooth ramp‑up despite space and capacity limits.

About Megatech

Megatech Industries is an international automotive supplier specializing in plastic interior and exterior components, headquartered in Vaduz, Liechtenstein, with operations including sites in Czechia. In 2025 the company was acquired by SAPA as part of SAPA’s global expansion.

~2,200 employees (global)

Presence in 9 countries

Czech sites include Plzeň and Jablone

Initial challenge

Integrate a new production project into an already running plant while solving capacity constraints and lack of space.

Project goal

Design and implement a comprehensive internal logistics concept, from goods receipt to dispatch, and prepare the plant for Start of Production.

Solution

Validating the concept with a digital twin

Logio designed the future internal logistics, aligned processes and systems, and used dynamic simulation to compare variants and de‑risk the SOP.

Solutions implemented

Production Ramp‑up Support

Dynamic Simulation

Simulation & Flow Analysis

Impact

Confident start of production with the right capacity

Smooth SOP ramp‑up, no surprises

Dynamic simulation de‑risked implementation and supported stable mass production start.

Right‑sized WIP and packaging

Model defined stock and container needs ahead of go‑live.

Verified machine utilization

Scenarios tested and validated capacity before changes on the shop floor.

End‑to‑end process readiness

Logistics from receiving to dispatch aligned with updated IS and new layout.

Make your SOP predictable

We tackled many supply chain challenges

Production planning validation for Strojmetal

Logio validated Strojmetal’s new production planning software and completed the implementation roadmap, reducing implementation risk and protecting critical planning know‑how in a highly specialised aluminium forging environment.

Suitability of the selected production planning module independently verified

Implementation schedule completed with missing activities, including workflows and data management

Lower risk of implementation delays and loss of key planning know‑how

Ramp‑up of an automated warehouse for Radegast

Logio secured the on‑time start of Radegast’s automated warehouse in Nošovice by coordinating on‑site ramp‑up, testing, and training when the supplier could not travel, enabling automated pallet handling between bottling and dispatch.

Availability improved from 96 % to 98 %

Inventory turnover time reduced by 8 %

Time to create orders reduced by 90 %