Production ramp‑up support

Hit target volumes faster and with fewer surprises.

Logio stabilizes new or scaled production by aligning capacity, materials, processes, and systems.

Using data‑driven planning, dynamic simulation, and supplier‑agnostic automation know‑how, Logio turns a risky ramp into a predictable plan with clear accountability and measurable outcomes.

Your challenges

What’s holding you back right now?

Plans ignore real bottlenecks and shift daily

Capacity and staffing do not match target volumes

Materials, tooling, and data are not ramp‑ready

ERP shows a plan, reality shows constraints

Automation scope is unclear, risk of sunk costs

When it matters

You’ll benefit when you are…

Launching a new product or variant on an existing line

Transferring production to a new site or supplier

Scaling volumes after pilot or PPAP approval

Preparing for automation or robotics in production

Verifying layout, cycle times, and buffers before go‑live

Balancing people and machine capacity across shifts

Synchronizing inbound materials and internal flows

Setting up ramp KPIs and reports for management

Outcomes

What we deliver

Stable plan to target volume

A phased ramp roadmap with gates, owners, and risks under control.

Bottleneck‑free flow

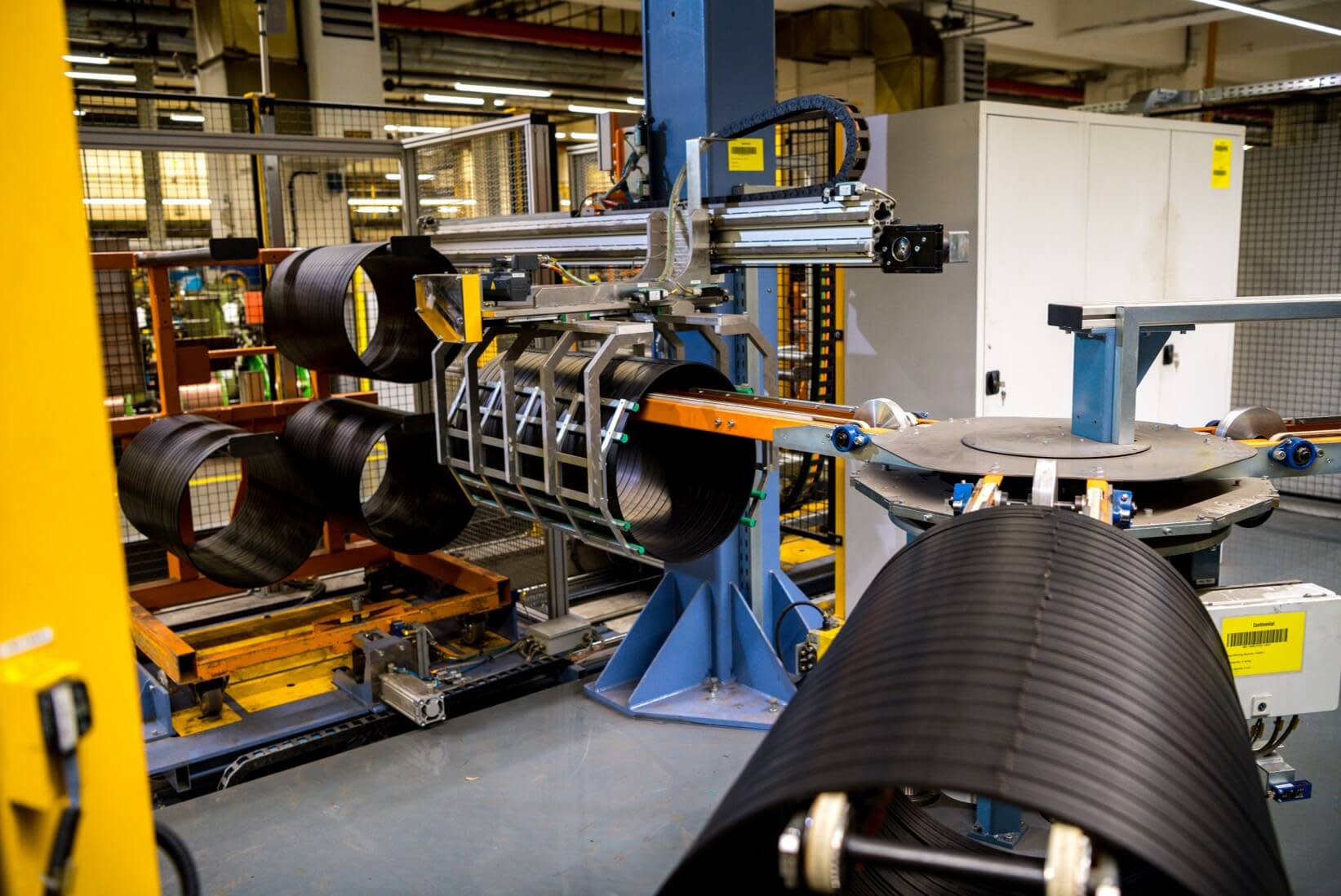

Verified line design and buffers using dynamic simulation and digital twin.

Right‑sized capacity

Human and machine capacity balanced to realistic demand scenarios.

Material readiness

Inbound, WIP, and FG policies aligned with takt and changeovers.

Automation with confidence

Feasibility, business case, vendor selection, and supervised commissioning.

Decision‑grade visibility

Live KPIs and augmented reporting for ramp steering.

What makes us different

Logio experts at your service

Hybrid team: operations consultants + system and automation architects.

Supplier‑agnostic approach with rigorous feasibility and business case.

Data‑first methodology backed by BI and advanced analytics.

Dynamic simulation to de‑risk layout, buffers, and throughput before go‑live.

Proven capacity planning for complex, multi‑workstation environments.

End‑to‑end delivery from concept to commissioning and ramp stabilization.

How AI and data strengthen your ramp

Logio uses AI where it truly adds value, combining it with mathematics and domain expertise. That means better demand signals, smarter inventory targets, and faster learning during early builds. The result is a ramp that adapts to reality rather than fighting it.

As a Microsoft Partner, Logio builds on a modern stack and proven engineering practices. VERITICO, Logio’s AI‑driven platform, has been recognized by Gartner among the top 25 solutions globally, reflecting years of focused investment and real‑world deployments.

Where Veritico helps during ramp

Veritico (Logio’s proprietary, configurable platform) supports demand forecasting, inventory management, and replenishment to ensure materials and components are available at the right time and place — across DCs and the shop floor touchpoints that feed the line. It centralizes data, automates orders, and provides one source of truth for supply decisions during ramp.

Case studies

We tackled many supply chain challenges

Reach stable output sooner

If your ramp is complex and time‑critical, Logio helps you align capacity, materials, and automation with a plan you can trust. Let’s talk about a data‑led ramp that delivers predictable results.