Production & automation design

Map the current state, test future scenarios, and design production and automation that work in real life.

Logio combines data, dynamic simulation, and vendor‑independent expertise to reduce risk, right‑size investment, and deliver scalable operations.

Use it when you prepare a new line or site, plan automation, or need to de‑bottleneck production.

Your challenges

What’s holding you back right now?

Unclear bottlenecks and true capacity limits

Layout and flows designed on slides, not by data

Automation options, no objective comparison

Business case risk, CAPEX and OPEX not validated

Fragmented systems, hard to plan people and shifts

Vendors push tech that does not fit operations

When it matters

You’ll benefit when you are…

Designing a new line, cell, or hall

lanning automation or robotics with multiple options

Validating CAPEX and OPEX before investment approval

Resolving throughput issues and queuing on lines

Balancing upstream and downstream buffers and WIP

Aligning layout, flows, and IS before go‑live

Preparing shift patterns and workforce for the target takt

Integrating production with warehousing and dispatch

Outcomes

What we deliver

Verified concept and business case

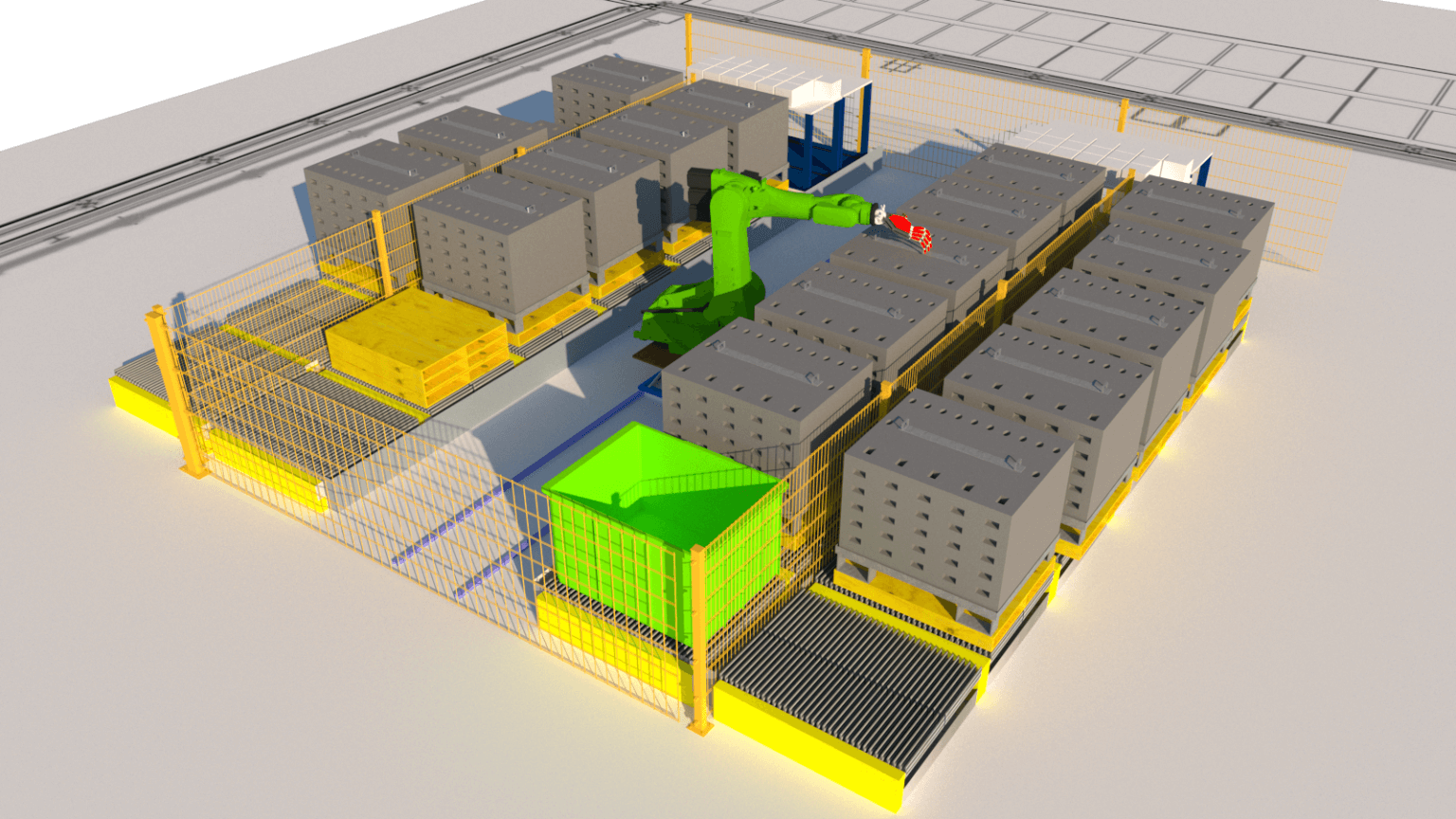

Validate scenarios with a dynamic 3D digital twin, including technology counts, robot utilization, response times, buffers, and cost impacts.

Right‑sized layout and flows

Produce external and internal layouts down to workstation micro‑layouts with material routes and buffer design.

Bottleneck elimination plan

Identify and remove capacity constraints, collisions, and idle times across the process.

Automation selection and RFP support

Compare manual, semi‑auto, and automated concepts, then run vendor‑neutral evaluations and negotiations.

Implementation roadmap with risks

Phase the rollout, quantify risks, and align IT, processes, safety, and construction impacts.

Shift and maintenance planning inputs

Provide scenarios for shifts, maintenance windows, and changeovers to protect availability and OEE.

What makes us different

Logio experts at your service

Vendor‑independent concept design that fits real needs, not catalogues

Digital twin for fast scenario testing and risk reduction before “digging” starts

Hybrid team of manufacturing consultants, system architects, and data scientists

From strategy to commissioning, including supervision and acceptance tests

Clear business case with CAPEX, OPEX, and sensitivity analysis

Data and AI‑first company

Logio treats design as a data problem. Dynamic simulation builds a digital twin of your planned or existing system. It lets decision‑makers test scenarios in realistic conditions, see how queues, buffers, and resources behave, and select a proven option before investing. This reduces additional costs at implementation and de‑risks timelines.

Logio is both a consulting and technology company. Beyond classic production design, the team brings forecasting, inventory science, and decision support to keep plans executable across the chain. That mix of mathematics, experience, and common sense is built into how projects are run and governed.

Case studies

We tackled many supply chain challenges

Design production and automation you can trust

If your operations are complex and decisions are high‑stakes, Logio will help you choose, validate, and implement the right concept with predictable outcomes. Let us talk about your target throughput, footprint, and timeline.