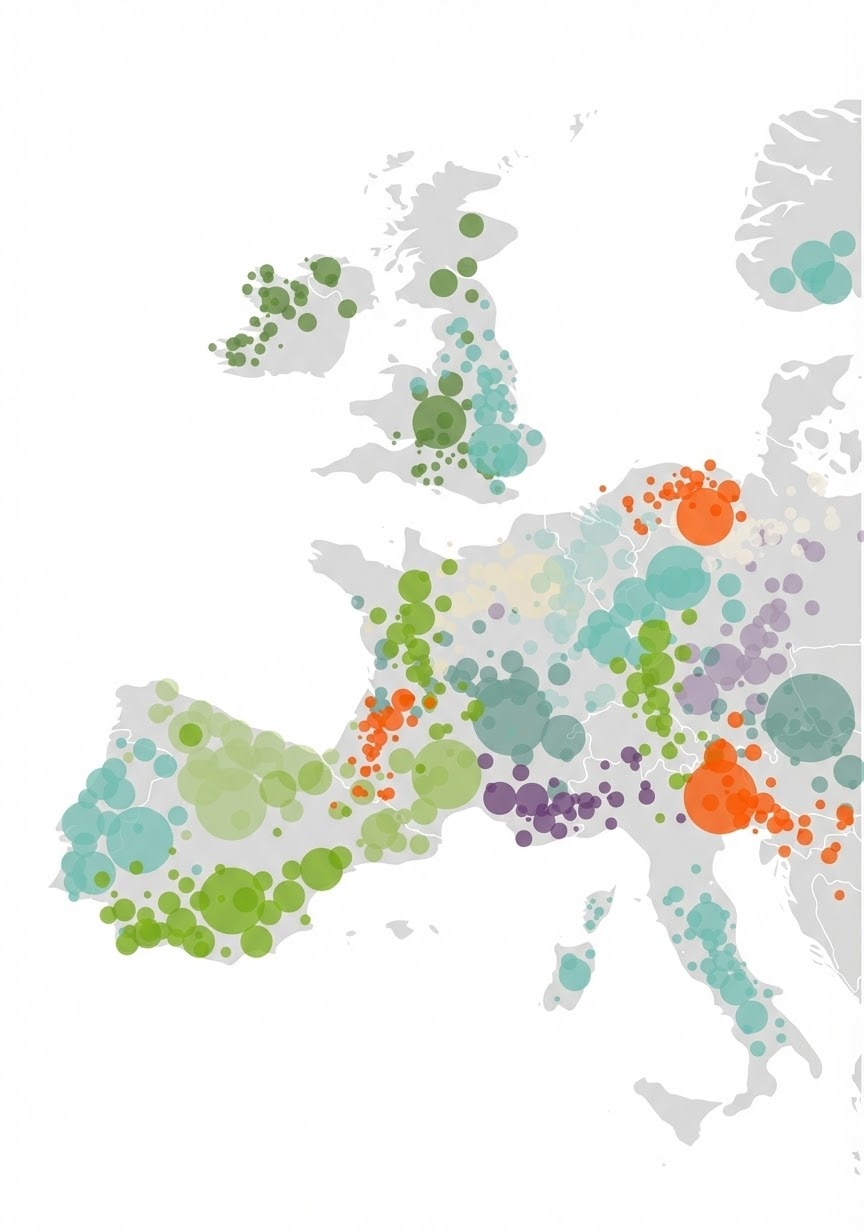

Distribution concepts

The right distribution concept sets service level and cost for years.

Logio designs DC roles, flows, and calendars that match customer promise, product mix, and growth.

Use it to decide DC types, x‑dock roles, and FTL/LTL balance.

Your challenges

What’s holding you back right now?

No clear role for each DC

Poor vehicle utilization and empty miles

Cost per drop varies without reason

Fresh vs. ambient flows clash

When it matters

You’ll benefit when you are…

Assigning products to DCs and routes

Balancing FTL/LTL across regions

Adding channels or markets

Redesigning delivery calendars

Outcomes

What we deliver

Defined DC roles

Clear modes: DC, x‑dock, hub, spoke.

Efficient loads

Better fill rates and time windows compliance.

Aligned assortments

DC‑product‑customer mapping.

Lower cost‑to‑serve

Transparent cost per order and route.

What makes us different

Logio experts at your service

Math‑driven concept choices and KPIs

Realistic constraints from drivers to docks

Experience across retail and manufacturing

Data and AI‑first company

Concepts are tested with data, not hunches. We model loads, regions, and SLAs to find the best operating picture.

Veritico

If wanted, Veritico supports distribution scenario modelling as part of broader supply chain planning.

Case studies

We tackled many supply chain challenges

Design distribution that keeps promises

If service level and cost vary by luck, redesign the concept.