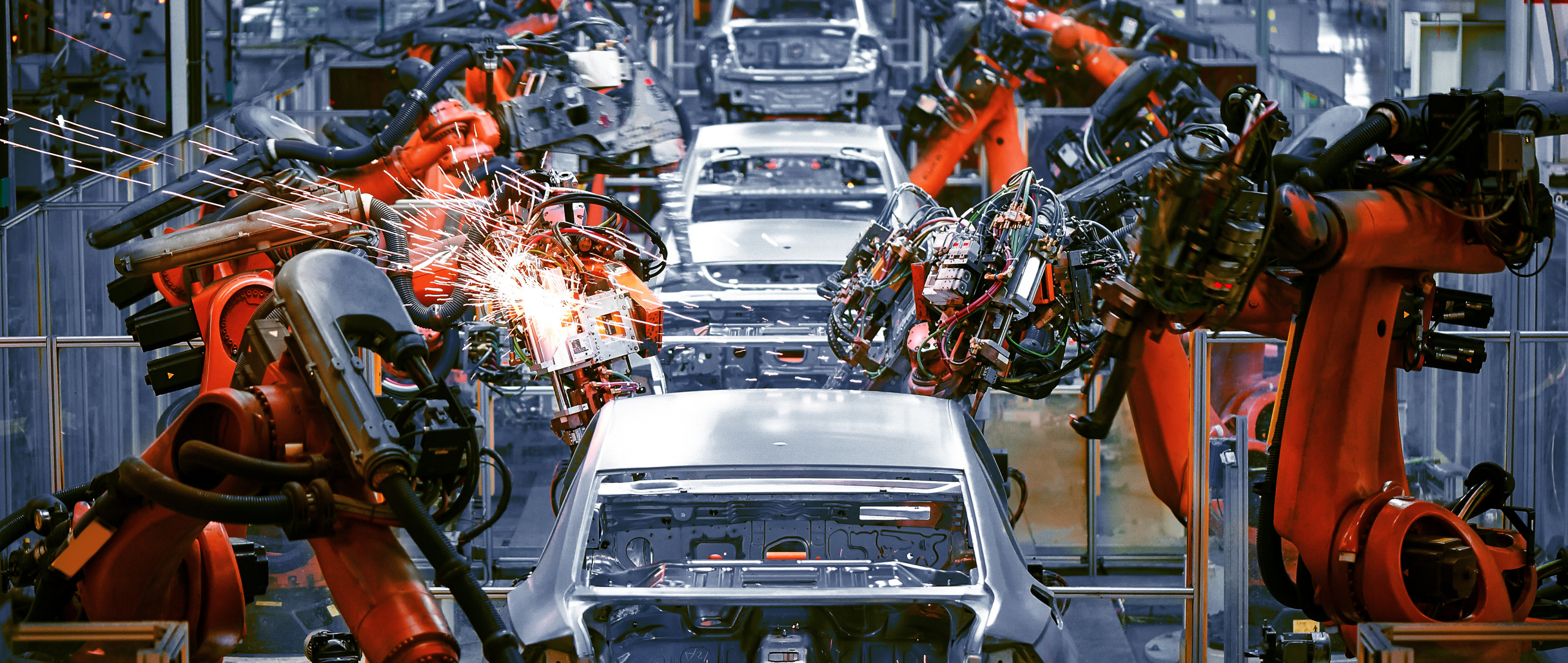

Automotive & Industrial Components

Faster line supply with lower production inventory

Logio supported an automotive manufacturer in designing and implementing a new supply system that secures the delivery of assembly parts from the warehouse to each stroke of the production line.

Outcome

The new system ensures that the right parts arrive at the right place and time, while integrating with five existing information systems. This reduced inventory tied up in production and shortened delivery time from warehouse to line.

Initial challenge

The client needed a new supply system for the production line that would secure precise delivery of assembly parts in the right quantity and at the right time from the warehouse to each stroke of the line. It also had to work reliably within an environment of multiple existing information systems.

Project goal

Define, source and implement a supply system that covers key supply processes, sets clear functional and technical requirements including security and maintenance, and integrates with five of the client’s information systems to support smooth and efficient production.

Solution

From SW specification to successful implementation

The focus was on clearly defined processes, robust technical parameters and secure integration with the client’s existing systems.

Solutions implemented

Implementation & Change Management

Tendering & Supplier Management

Technology Integration & Handover

Impact

Reliable line supply with lower inventory and faster deliveries.

Lower inventory in production

The new supply system reduced the amount of material stored directly in production while still securing availability of parts at the line.

Shorter delivery time to the line

Material now reaches the production line faster thanks to a controlled supply process between warehouse and individual line strokes.

Reliable integration with five information systems

The solution was designed to communicate with five existing systems, which supports data consistency and stable operation.

Clear and secure system specification

A complete functional and technical specification defines processes, security requirements and maintenance standards, which reduces implementation and operational risk.

Smooth implementation of the new management system

The documented requirements and joint work on the tender enabled a controlled transition to the new system without disruption to production.

Want to modernise supply to your production line

If your production line depends on multiple systems and manual coordination, we can help you define, source and implement a supply solution that connects your systems, reduces inventory in production and speeds up deliveries to the line. Let us know what challenges you face.

We tackled many supply chain challenges

Automated forecasting and ordering for EMOS

EMOS consolidated planning on Veritico to automate forecasting and ordering across 1,300+ products, achieving 98% availability and a 17% reduction in stock working capital.

98 % stock availability

–17 % stock working capital