Automotive & industrial

Reliable short‑term sales planning

Logio worked with SKF during the COVID‑19 disruption to design and deploy a short‑term sales forecasting model at product‑line level.

Outcome

Up to 90% forecast accuracy in unstable market conditions enabled faster, more confident planning.

Up to

0 % forecast accuracy

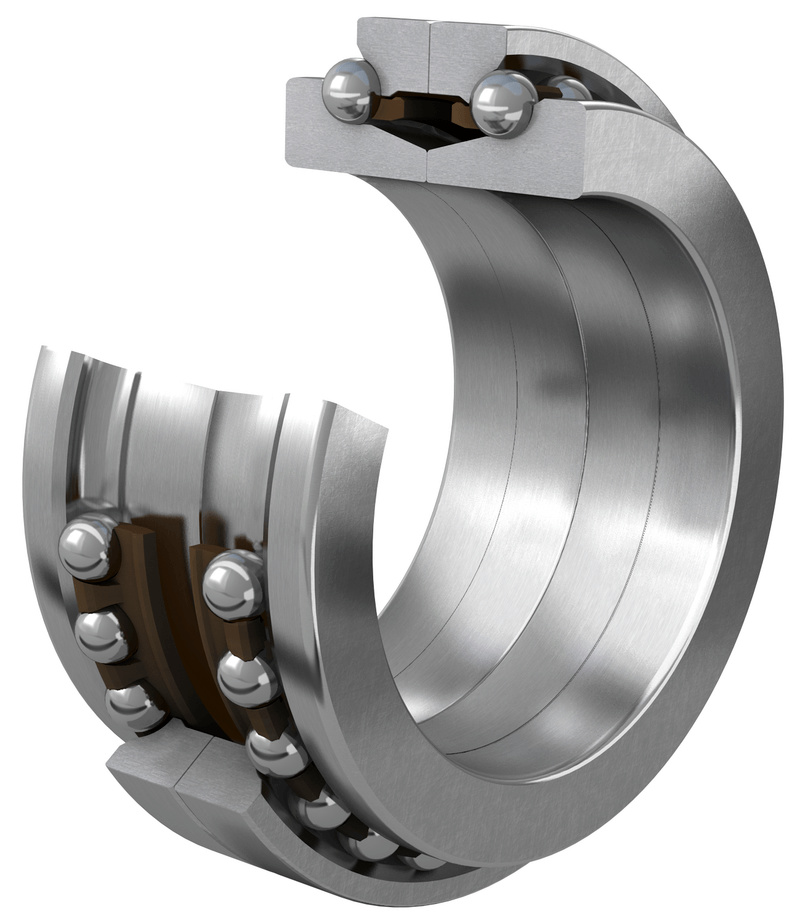

About SKF

SKF is a Swedish manufacturer of bearings, seals, lubrication systems and related services, founded in 1907 and headquartered in Gothenburg. The company operates in around 130 countries with more than 40,000 employees and an extensive distributor network.

Founded in 1907

40,000+ Employees

Presence in ~130 countries

Initial challenge

Sales channels were restricted and supply flow slowed during the coronavirus crisis, making short‑term demand uncertain.

Project goal

Create an agile short‑term sales forecasting process to mitigate the impact on the business and its customers.

Solution

Making short‑term demand visible

We co‑designed an agile forecasting process and built a short‑term sales model at product‑line level. It gave SKF near‑term visibility to plan with confidence during COVID‑related disruption.

Solutions implemented

AI Integration

Process Optimization

Impact

Confident decisions in a volatile market

Higher forecast precision

Up to 90% accuracy at product‑line level supported daily decisions.

Faster planning cycles

Teams reacted more quickly to sudden demand shifts.

Better cross‑functional alignment

Sales and supply teams worked from a shared view of near‑term demand.

Reduced uncertainty for customers

Clearer order guidance during volatile periods.

Take control of store availability

If manual ordering slows your teams, we can automate replenishment and pricing with Veritico. Let’s talk about a practical roadmap to higher availability and lower effort.

We tackled many supply chain challenges

Production ramp up support for Grupo Antolin Turnov

Grupo Antolin Turnov secured the on‑time launch of a new automotive interior production line by combining crisis management, material flow design and dynamic simulation with Logio’s support. The project delivered a validated logistics concept and reduced risk at start‑up.

New interior production started on the original target date.

New logistics concept for the line prepared, implemented and executed.

Key risks and bottlenecks verified and mitigated in simulation before go‑live.

Distribution planning for a vaccine network

A long‑term partnership moved vaccine distribution from manual planning to a robust routing and territory modeling setup, enabling quick responses to policy changes and strict handling conditions.

30 minutes to plan daily routes for the entire network

Hundreds of doctors’ offices covered

15 years of continuous cooperation